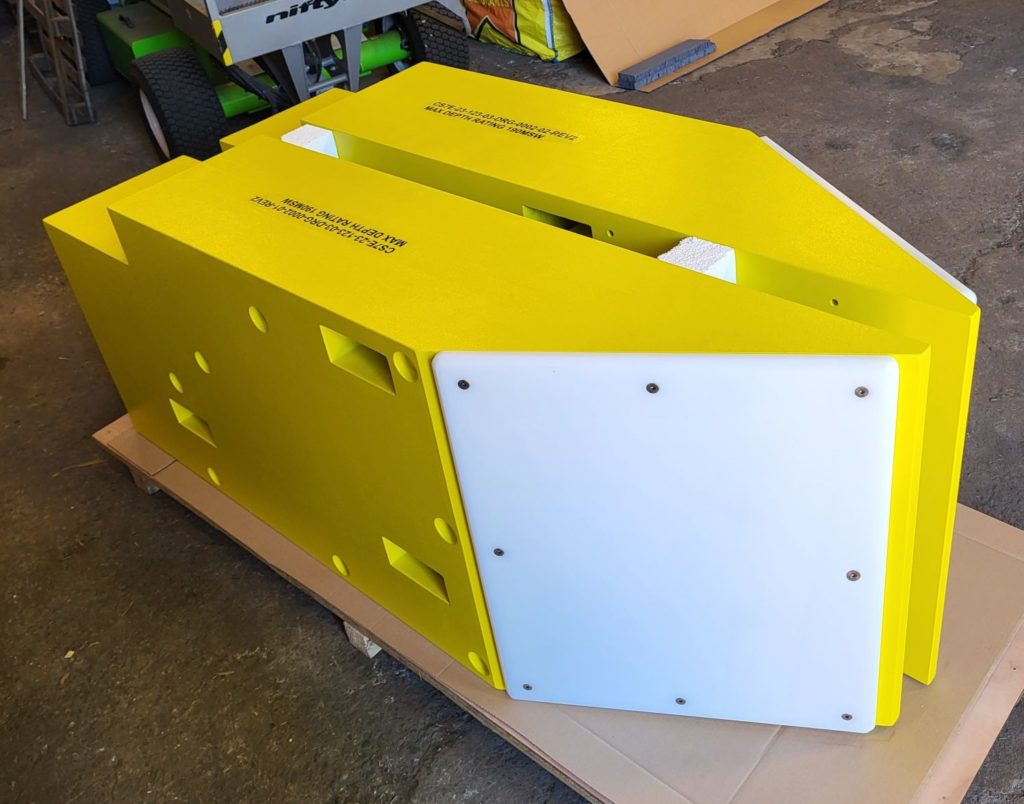

We supply custom buoyancy blocks for ROV tooling systems, with in-house design support and CNC machining. Our finished blocks are produced by machining and bonding standard buoyancy raw material blocks available from a number of leading suppliers. We can supply finished blocks produced from syntactic foam or PVC material depending on your application.

Many different material options exist for depth rating, density and coating to suit your project and budget. We can advise the best options to suit your project and application.

Our most popular foam materials which we generally have material in stock for are:

Deep Water Syntactic Foam 3000M depth rated, density 435 kg/m3 (for deep water applications)

Shallow Water PVC Foam 300M depth rated, density 250 kg/m3 (for North Sea applications)

We can supply simple small blocks or more complicated larger blocks, larger blocks are resin bonded and vacuum pressed. We have a 3D design service where we can design your blocks for your with a focus on manufacturability (DFMA) to ensure your design is straightforward to produce and reduce material wastage.

All our projects begin life in 3D Solidworks where they are optimised for production and then process via our Vcarve Pro software where the production routines are set for machining on our large format CNC.

We can supply up to 4000m rated syntactic buoyancy for deep water operations or more cost effective PVC formulated buoyancy for North Sea projects. It is important that the type of buoyancy is specified correctly for your project as the buoyancy required for a rental ROV Tooling is completely different to that required for a decommissioning project in the North Sea on a cost basis.

We can help design the blocks for you and perform buoyancy calculations including centre of gravity and centre of buoyancy calculations for your equipment.

If you have an upcoming project it is highly recommended speaking to us first as we can assist and advise on the materials, grades, costs, lead-times, manufacturability, block features, block mounting, lifting inserts and coating systems to ensure you get the best solution for your project.

We generally have material in stock for fast turn-around however a typical lead-time for spray coated buoyancy products from enquiry to delivery is 6 weeks.